|

Tin Whiskering |

|||

|

Experiments, 2008/08/03

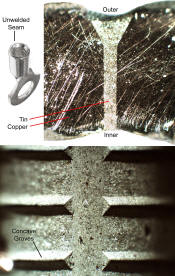

Based on the evidence of whisker growth relegated to the tin filled

mechanical interface for the ring lugs shown below, I have begun an

investigation into the actual mechanism of whisker growth from pure metal

coatings. |

|||

|

Images

|

|||

1. Crystal growth |

|||

| Whisker Examples from My Inventory | |||

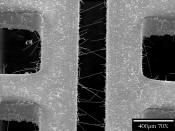

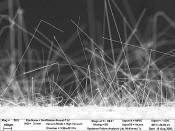

| The images below are from a pure tin plated

copper lug from a bag of about 50 lugs that have been there for several

years. While all the lugs had whiskers; 75% had whiskers around 500

microns long, 20% had whiskers around 1000 microns long and 5% had

whiskers up to 3000 microns long than went more than half way across the

barrel. No whiskers were noted on any of the parts anywhere but over

the internal seam: For the exposed surfaces outside the barrel this

could be due to mechanical breaking of forming whiskers when contacting

other parts in the bag, this could not be the case for the non-seam

surface within the barrel. Pulling apart the barrel seam, the inclusion of air pockets in the tin plating within the seam indicates the parts were dip-plated, as opposed to electro-plated. |

|||

|

|

|

|

|

External Image Collection |

|||

|

|

|

|

|

Technical Documents |

|||

| Alert | Anecdote | Gold Whiskers | Mitigation |

| Mitigation | Risks | Tin Commandments | |

|

External Links |

|||

| ACI | CALCE | EMPF | NASA |

| NEMI | NIST | SolderTec | |